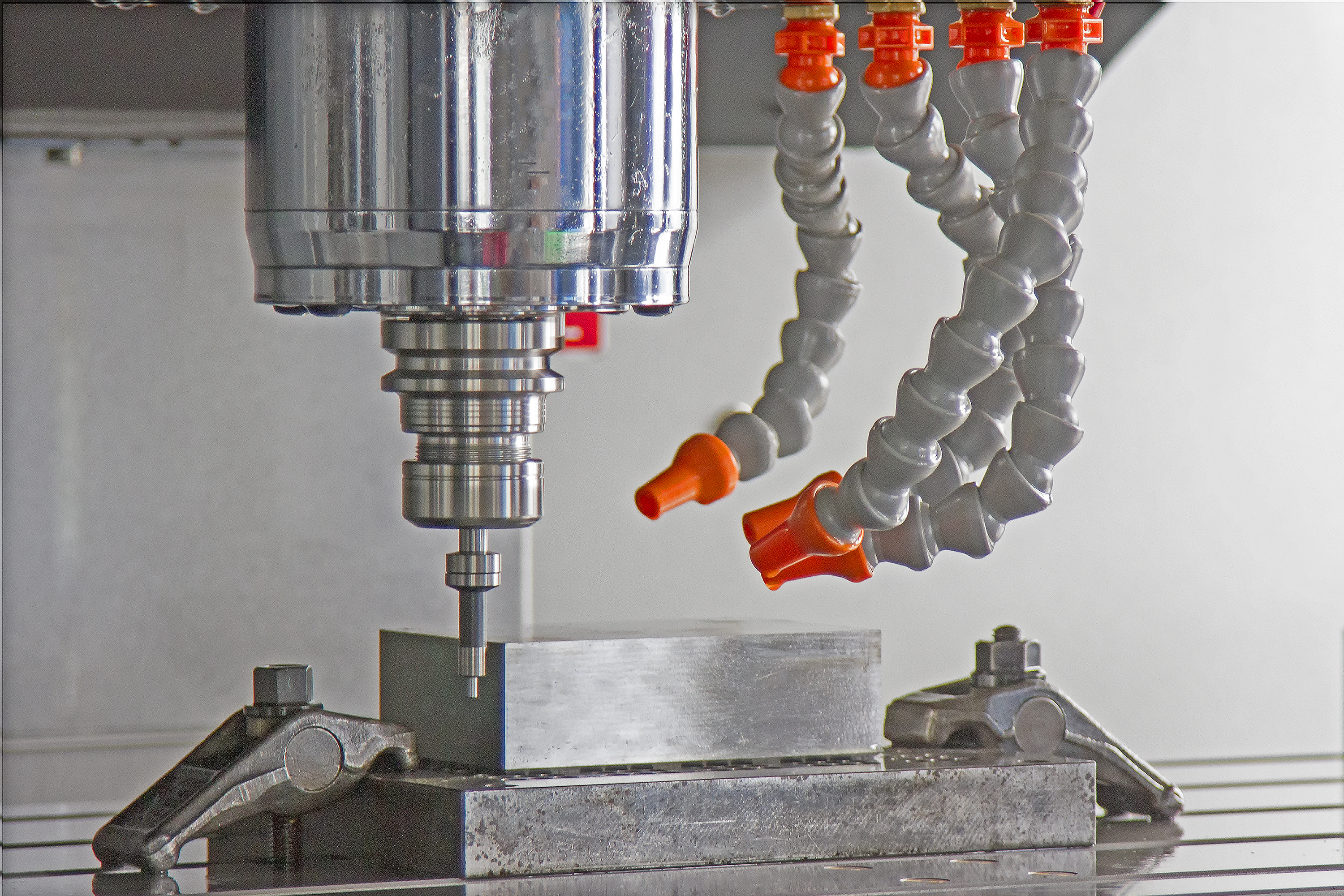

Nyob rau hauv lub realm ntawm manufacturing thiab engineering, Computer Numerical Control (CNC) machining tau revolutionized txoj kev Cheebtsam thiab cov khoom tsim.Qhov kev siv tshuab thev naus laus zis no ua rau muaj tseeb thiab ua tau zoo ntawm cov khoom siv ntau yam, ua rau muaj ntau yam kev lag luam xws li tsheb mus rau aerospace, los ntawm hluav taws xob mus rau cov khoom siv kho mob.Txawm li cas los xij, nrog ntau cov ntaub ntawv muaj, xaiv qhov zoo rau koj qhov project CNC tuaj yeem ua haujlwm txaus ntshai.Tsis txhob ntshai, rau phau ntawv qhia no yuav coj koj los ntawm cov xwm txheej los txiav txim siab thaum xaiv cov khoom siv CNC zoo meej rau koj cov kev xav tau tshwj xeeb.

1. Nkag siab txog koj qhov project yuav tsum tau

Ua ntej dhia mus rau hauv lub ntiaj teb ntawm cov ntaub ntawv, nws yog ib qho tseem ceeb kom nkag siab meej txog koj qhov project specifications.Xav txog tej yam xws li:

Cov kev xav tau ua haujlwm: Cov khoom kawg yuav siv rau dab tsi?Puas yog ib qho kev tivthaiv, ib qho khoom siv zoo nkauj, lossis ib feem raug rau qhov kub thiab txias los yog corrosive ib puag ncig?

Design intricacies: Puas yog koj tus qauv tsim muaj cov ntsiab lus sib txawv lossis cov duab geometry nyuaj uas xav tau cov khoom siv tshwj xeeb?

Muaj pes tsawg leeg thiab pob nyiaj siv: Koj xav tau pes tsawg feem, thiab koj cov peev nyiaj rau kev yuav khoom yog dab tsi?

Los ntawm kev txhais cov kev txwv no, koj tuaj yeem nqaim cov khoom siv uas zoo tshaj plaws rau koj qhov project.

2. Cov khoom siv

Cov ntaub ntawv sib txawv muaj cov khoom sib txawv uas tuaj yeem cuam tshuam qhov kev ua tau zoo thiab cov yam ntxwv ntawm koj cov khoom kawg.Qee cov khoom tseem ceeb uas yuav tsum xav txog muaj xws li:

Lub zog thiab durability: Nyob ntawm daim ntawv thov, koj tuaj yeem xav tau cov ntaub ntawv nrog lub zog tensile siab, cuam tshuam tsis kam, lossis hnav tsis kam.

Machinability: Xav txog qhov yooj yim uas cov khoom siv tuaj yeem ua haujlwm siv cov txheej txheem CNC.Qee cov ntaub ntawv yuav xav tau cov cuab yeej tshwj xeeb lossis kev txawj ntse.

Thermal thiab hluav taws xob conductivity: Rau daim ntawv thov uas muaj cua sov dissipation los yog hluav taws xob conductivity, xaiv cov khoom uas tsim nyog thermal thiab hluav taws xob khoom.

Corrosion resistance: Yog tias koj qhov project yuav raug rau qhov hnyav ib puag ncig lossis tshuaj lom neeg, xaiv cov khoom siv nrog cov khoom tiv thaiv corrosion.

3. Cov khoom siv xaiv

Thaum koj tau txheeb xyuas koj qhov project xav tau thiab cov khoom siv uas xav tau, tshawb xyuas ntau yam khoom siv muaj rau CNC machining.Qee cov ntaub ntawv muaj xws li:

Hlau: Txhuas, stainless hlau, tooj dag, titanium, thiab tooj liab yog cov kev xaiv nrov rau lawv qhov zoo tshaj plaws lub zog-rau-hnyav piv, machinability, thiab versatility.

Plastics: ABS, acrylic, nylon, thiab polycarbonate muab lub teeb yuag, kev daws teeb meem zoo nrog tshuaj lom neeg zoo thiab tsim qauv yooj yim.

Composites: Cov pa roj carbon fiber ntau, fiberglass, thiab laminates ua ke muaj zog nrog lub teeb yuag, ua rau lawv zoo tagnrho rau kev siv aerospace thiab tsheb.

4. Xav txog Machining Constraints

Thaum CNC machining muaj qhov ua tau zoo tshaj plaws thiab hloov tau yooj yim, qee cov ntaub ntawv tuaj yeem tsim teeb meem thaum lub sijhawm machining.Cov yam ntxwv xws li cov cuab yeej hnav, nti tsim, thiab qhov chaw tiav tuaj yeem cuam tshuam rau kev xaiv cov khoom.Nws yog ib qho tseem ceeb los sab laj nrog cov kws paub txog CNC machinists uas tuaj yeem muab kev nkag siab txog qhov ua tau thiab kev ua kom zoo ntawm cov khoom siv tshwj xeeb.

5. Qauv thiab Kev Xeem

Ua ntej cog lus rau kev tsim khoom loj, nws raug nquahu kom tsim cov qauv siv cov khoom sib txawv los ntsuas lawv qhov kev ua tau zoo tiv thaiv koj qhov project yuav tsum tau ua.Ua cov kev ntsuam xyuas zoo thiab kev tshuaj xyuas los ntsuam xyuas cov yam ntxwv xws li lub zog siv tshuab, qhov tseeb qhov tseeb, thiab qhov ua tiav.Cov txheej txheem rov ua dua no tso cai rau koj los kho koj qhov kev xaiv cov khoom siv zoo thiab ua kom zoo rau koj tus qauv tsim kawg.

Xaus

Xaiv cov khoom tsim nyog rau koj qhov project CNC yog qhov kev txiav txim siab tseem ceeb uas tuaj yeem cuam tshuam qhov zoo, kev ua tau zoo, thiab tus nqi-zoo ntawm koj cov khoom kawg.Los ntawm kev nkag siab txog koj txoj haujlwm xav tau, xav txog cov khoom siv, tshawb nrhiav ntau yam khoom siv, thiab koom tes nrog cov kws paub txog CNC, koj tuaj yeem ntseeg siab xaiv cov khoom zoo tshaj plaws uas haum rau koj lub zeem muag thiab lub hom phiaj.Nrog rau kev ua tib zoo xav thiab paub txog kev txiav txim siab, koj yuav pib taug kev mus rau CNC machining kev vam meej, qhib qhov tsis muaj qhov kawg rau kev tsim kho tshiab thiab kev ua tau zoo.

Post lub sij hawm: Mar-26-2024